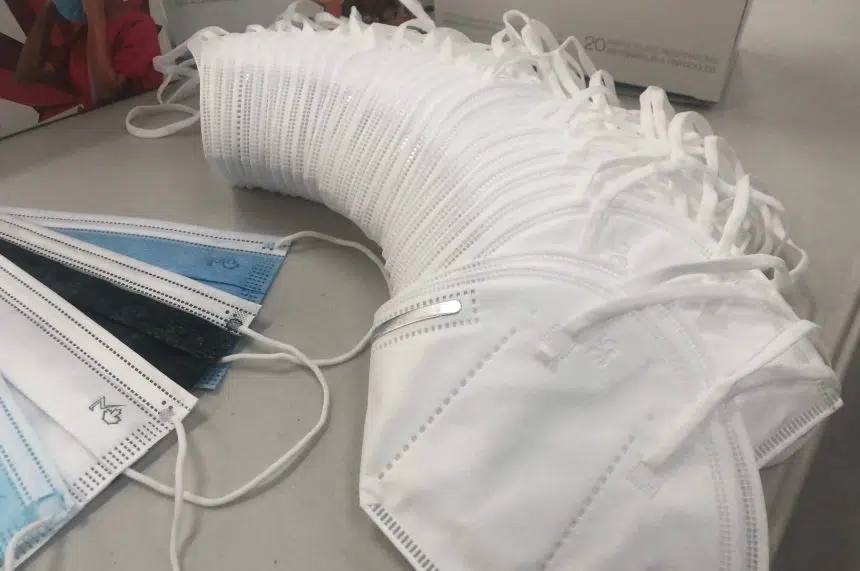

A University of Regina engineer has found a new purpose for single-use face masks, keeping thousands of them out of landfills.

Denise Stilling, an associate professor in industrial systems engineering at the University of Regina, said the pandemic created a flood of single-use plastics in the form of medical supplies and personal protective equipment like masks.

“It was estimated, during the height of the pandemic, that globally there were millions of these masks being used and discarded daily,” she said.

Stilling specializes in research geared towards finding alternate uses for single-use plastics or polymers.

“Our strategic plan here at the University of Regina is for sustainability, and to create the world that we want to live in,” Stilling said.

The researcher said she started repurposing grain bags, and took on a similar project with polypropylene face masks.

Stilling said she took masks and added materials such as crushed tires, sand, dirt, and even crop residue to innovate new materials. She then examined the materials’ properties, including strength, durability, resilience, acoustic sound absorption and moisture absorption. From there, the researcher was able to create some prototypes.

Stilling estimated she’s kept thousands of masks from ending up in landfills.

She has created tiles from polypropylene face masks mixed with crushed tires and sand. The tiles are nonstructural, meaning they won’t replace traditional building materials in homes, but they can be used as paving tiles to outline landscape features, like gardens.

Another example of the researcher’s work, which hasn’t been tested fully yet, is using less polypropylene and more crop residue to create an acoustic damping material, which could be used to replace acoustic tiles in office buildings to absorb sound and reduce noise levels, she explained.

Manufacturing the materials to make test samples and prototypes is done at the U of R, Stilling said, but there is lots of potential for the new materials to reach the market.

“We still need that entrepreneur to come forward and make it an industrial product, and then distribute it for commercial use,” she said.

If the repurposed tiles break or disintegrate, she said they can be melted down and reused to stop pollution from making its way into lands, waterways and landfills.

The researcher said her team collects masks from recycling bins around the university campus, and has integrated the project into her lessons at the University. Grad students take the masks apart to be manufactured into the new materials.

By giving her students the opportunity to experience the recycling process, Stilling said students will be highly qualified to take what they’ve learned and give back to society after they graduate.